Quality is the most important aspect of the L'bardi brand. While profit is important for all businesses it is not our core goal, our core goal is to provide the highest quality shoes at the lowest price possible, all the while conserving Italian craftsmanship, which has unfortunately become a dying art. L'bardi shoes are of higher quality than all the major fashion labels, yet we apply a lower profit margin, which allows us to retail our shoes at a lower price. Our aim is to improve the overall style of men and women worldwide by making luxury accessible to everyone and to educate the consumer on the importance of investing in quality, which has become evermore important with the increase in low quality fast fashion labels and luxury fashion labels skimping on quality in the search of higher profits.

Personalized just for you

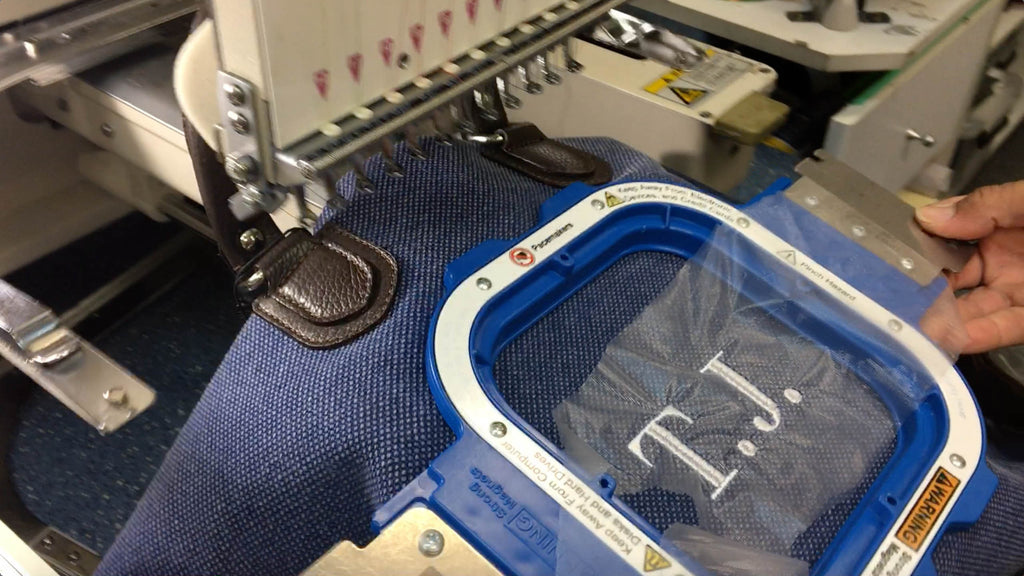

Personalization is a large part of the L'bardi experience, we combine expert Italian craftmanship with unique personal details, to make each and every product suit your needs and personality.

Personalized just for you

Personalization is a large part of the L'bardi experience, we combine expert Italian craftmanship with unique personal details, to make each and every product suit your needs and personality.